THE TECH DIARY: How the e-kart works

Technology Team

Total Karting Motorsport

Before we discuss recent developments in the new year, it might be useful to know the ins and outs of how the e-kart works.

All Electric Vehicles are composed of a battery, a control system, a motor and a cooling system. The battery is a common way to call what is in reality one or more battery packs. At the moment we have two e-kart categories, Bambino that has one battery pack and Cadet that has two battery packs.

THE BATTERY

Each battery pack is composed of almost a hundred cells. The cells are the real units, and each is similar to the battery that we can buy in a shop in terms of dimensions and capacity. Of course, we are speaking about rechargeable cells here.

There is a significant effort to find the right place in the kart to allocate these battery packs. Each one in fact weights around 9Kg and is 400x160x90 mm in dimension.

For the Bambino the location is on the left side of the driver and for the Cadet there is one battery pack on the left and one on the right.

To build the next race kart, that is a Junior, we expect to need more battery packs. The number of batteries not only dictates for how long the kart can run but also at what power. We have chosen to run below 60V and there is a limitation for each battery to stay below a certain current and we know that the power is voltage multiply by current. This then dictate the maximum power.

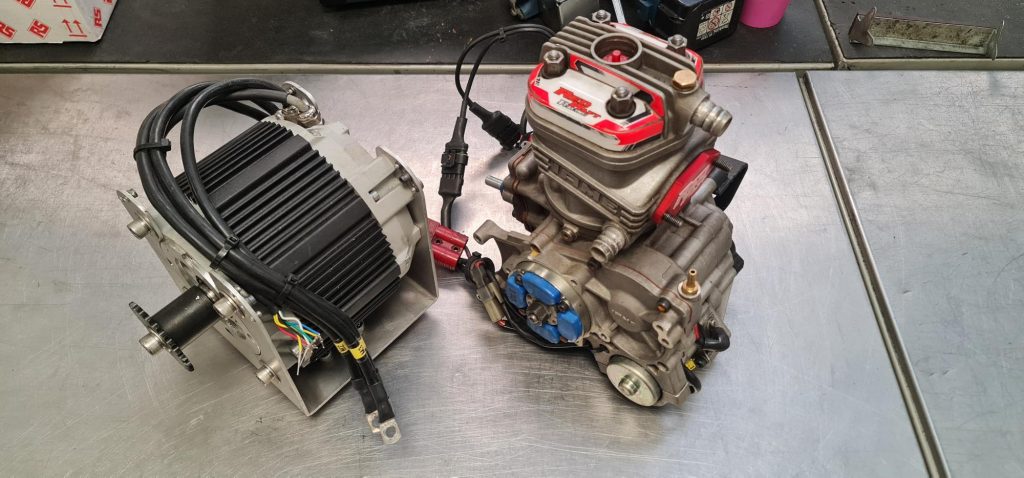

THE MOTOR

CONTROL SYSTEM

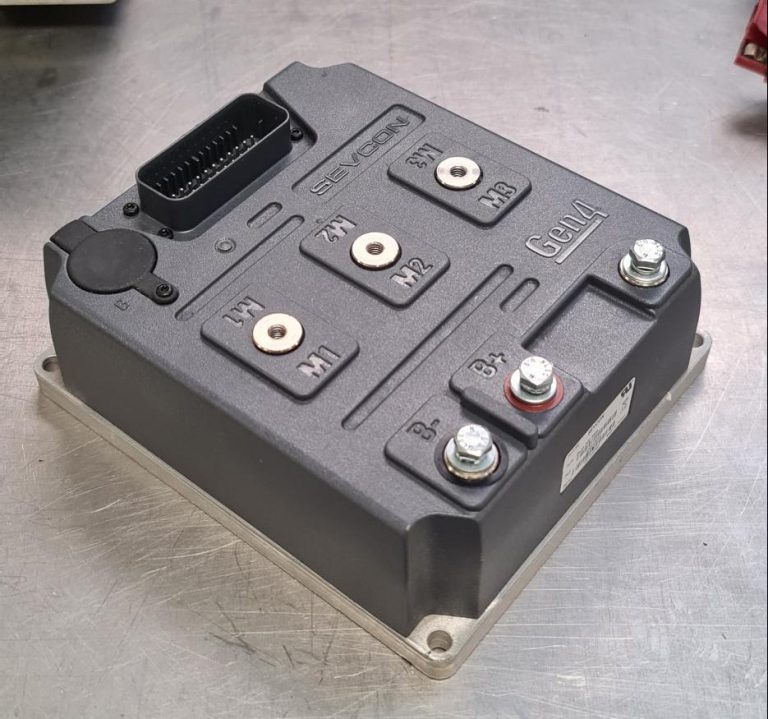

So we have the power from the batteries and we can convert that into mechanical power in the motor, but we cannot just connect the two as the motor requires AC (Alternate Current) to work while the batteries only give DC (Direct Current) and also we need to modulate the power.

There are two parameters relevant for AC, the amplitude and the frequency. In our houses the amplitude is 220V and the frequency is 60Hz, for example.

The PMAC motors work by having the rotational speed of the rotor synchronous (that is the reason of the name) to the magnetic field. There is a linear relationship between the rotor speed and the current frequency that generates the magnetic field in the stator so by changing the frequency we can change the rotational speed.

This means that to control the motor we need to change the frequency of the current. The particular part of the control unit that does that is called the Inverter.

This alone would not be enough as we also need to change the amplitude of the current to give more or less power. So there are complex operations to be done in order to have the current amplitude and frequency changing in the right way and this is done by the control unit.

Another important part is the encoder that allows to control the position of the rotor in the motor.

The control unit takes the input from the driver, the throttle position through a potentiometer installed in the pedal. Inside the control unit we have previously programmed the torque request for each position of pedal and the control unit convert that request in a current amplitude and frequency.

The control unit will also make sure that the system is not causing problems so if it detects for example a temperature that is too high in a component, it will cut down the power progressively. There are several controls like that and for some the units will decide to stop the functionality, returning an error to help in detecting what has gone wrong.

Another function of the control system is to be a collector that stores data which helps in understanding an issue or just the functioning in certain conditions included in dynamometer testing.

In the control units are also stored the parameters that allow to run the kart in the correct power mode. These parameters are the torque maps. We program all the karts with the same torque maps so that the performance on each kart, in terms of power delivery, is the same for all. We can then monitor that using the output from the control unit that will be part of a future article.

COOLING SYSTEM

The efficiencies of electric power units are by far higher than ICE systems. Nevertheless, the efficiency is still not 100%, so some part of the energy will be transformed into heat.

This means that we need to dissipate the heat in some way. For the Bambino and the Cadet we are able to dissipate it using just air but the Cadet kart is not too far from the limit to be air cooled. Any more powerful category, such as a Junior kart, will probably need a water cooled solution for the motor or at least a more optimised air cooling solution. This has to be taken into account as it will increase the total weight of the kart and will also have an impact on the layout of the vehicle.

CONCLUSIONS

To bring this all together, there are several challenges we face in order to electrify a kart.

- We need to find a place for all the batteries, this task is more and more difficult as the power increases.

- There are cooling requirements that can play a role both in terms of weight and dimension/layout.

- Batteries are big and heavy so need to be allocated properly to the chassis, considering weight distribution that has an important effect on handling.

- The control system is very important and has to be capable of data storage as well.

- The motor also has to be located in a very solid way and needs to be cooled enough so that the power can be consistent through the running.

We hope that’s given you an interesting insight into how the e-karts work and the planning that goes behind them. Join us in the New Year for more updates on what the team has been working on!

More from the Tech Diary

Blog | September 2021

Author: Rob Smedley

The biggest challenge we have faced as a group of engineers lies in understanding and perfecting the Control System. This is effectively the brain of the kart and dictates how each of the principal drivetrain components communicate with each other, across the almost infinite number of possible input scenarios.