THE TECH DIARY: Maintaining Parity and Post Event Processes

Sammy Bryan | Technology Team

Total Karting Motorsport

Mechanical Efficiency

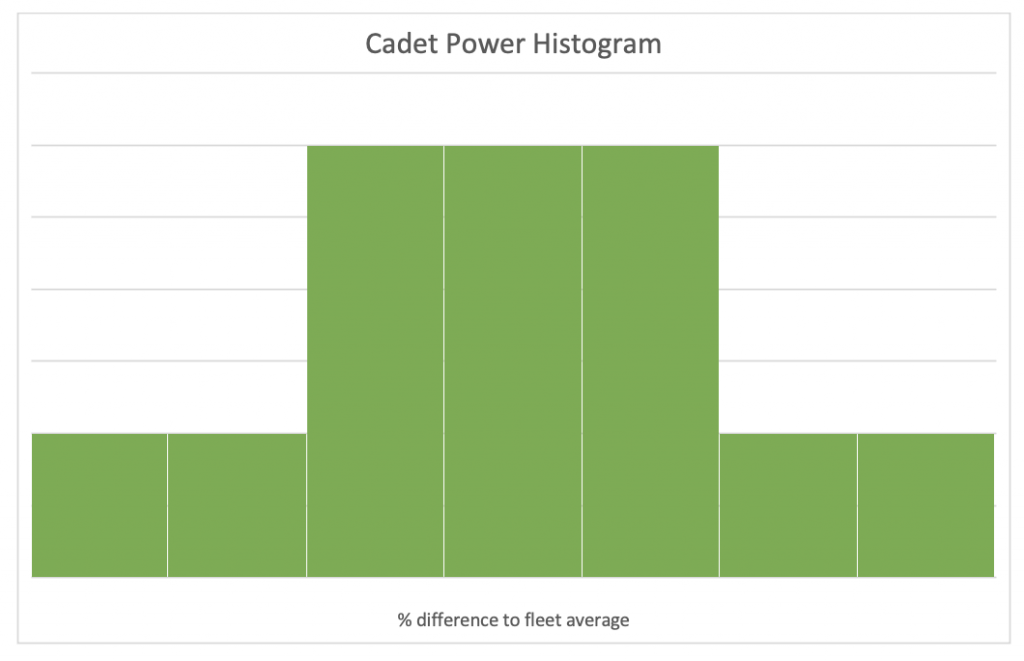

The efficiency of any mechanical system is never going to be identical however, the power output of electric motors is a lot more controllable than petrol engines: petrol engines have a lot of moving parts compared to electric motors that only have one moving part, reducing the number of variances and making them easier to control.

This means that the parity between power units is much higher with electric and they operate within tighter power tolerances of each other compared to petrol engines.

What is Dynamometer Testing?

Regular testing of the power units is carried out to ensure these continue to operate within these tight tolerances therefore providing parity across the grid. This is done every 4 races (or sooner if the kart requires investigation) by fitting the kart onto the ‘rolling road’, officially known as a wheel dynamometer, or ‘dyno’.

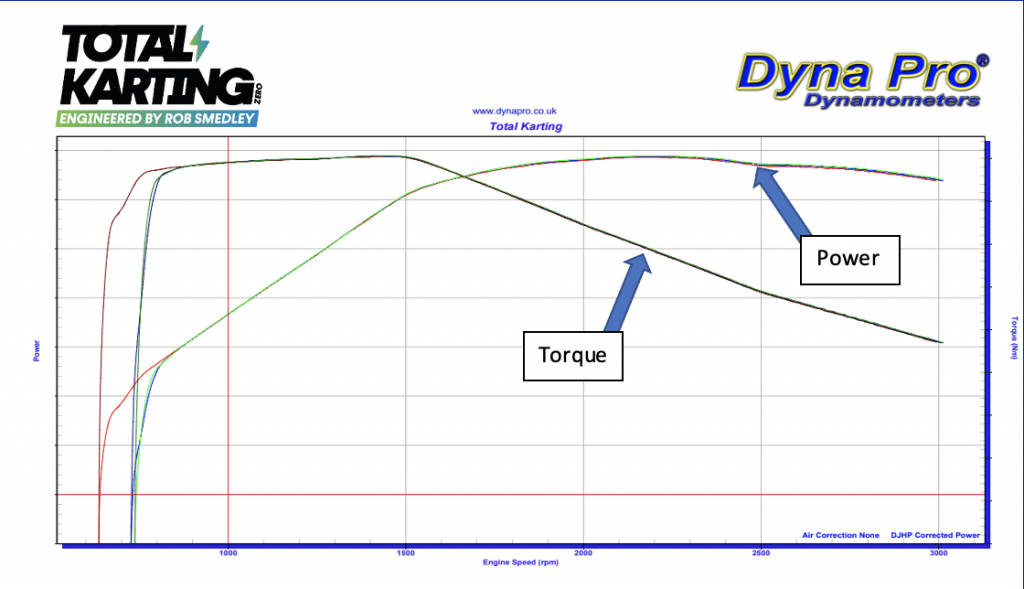

The machine measures the torque produced by the driven wheels of the kart. The dyno works using a big metal drum, just protruding from the floor, which the rear wheels sit on when the front of the kart is strapped down and secured in place. When the accelerator is pressed, it spins this drum. We calculate the power of the karts by measuring how fast the drum is spun up; We know how heavy the drum is and how much force is needed to make it spin so we can work this backwards to calculate the power. The dyno we use at Total Karting Zero is a DynaPro T62.

When testing, it’s important to only change one thing at a time so we know what influence each one change has on the results. Using the dyno is a very accurate and controlled method of measuring the power output of the karts, as it wouldn’t be possible to get the same level of accuracy just from track testing alone since there can be too many variables (e.g. influence from the weather, driver inconsistency, other karts on track etc.) Instead, the dyno sits in a specially made, soundproofed room where our engineers can carry out the tests and experiments time and again knowing the conditions are all the same.

When the karts are fitted to the dyno, we are able to:

- Measure multiple data channels from the onboard control unit, the same as we can measure at the track

- Record data directly from the batteries

- Measure the electrical current being discharged from the batteries, independently to other measures

- Measure power output

- Measure torque figures

The latter two points are measured by the dyno itself, an example of the results is shown below and demonstrates how repeatable the measurements are- in the graph there are three ‘tests’ but the lines are so close together it can be hard to see all three at once.

It shows the torque and power curves of a TKZ e-Kart. As is normal for electric motors, maximum torque is delivered at lower speeds, giving the e-karts unrivalled acceleration performance.

How do we ensure parity at events?

If at a race weekend an E-Kart is reported to the team to be unfair because of a perceived difference in performance we first look at how that kart is performing relative to the others. We look at the drivers form in previous rounds, the drivers form so far during the weekend, we compare lap times and average speeds. To collect more information about the performance, we need to fit dataloggers and send the kart out for a second session.

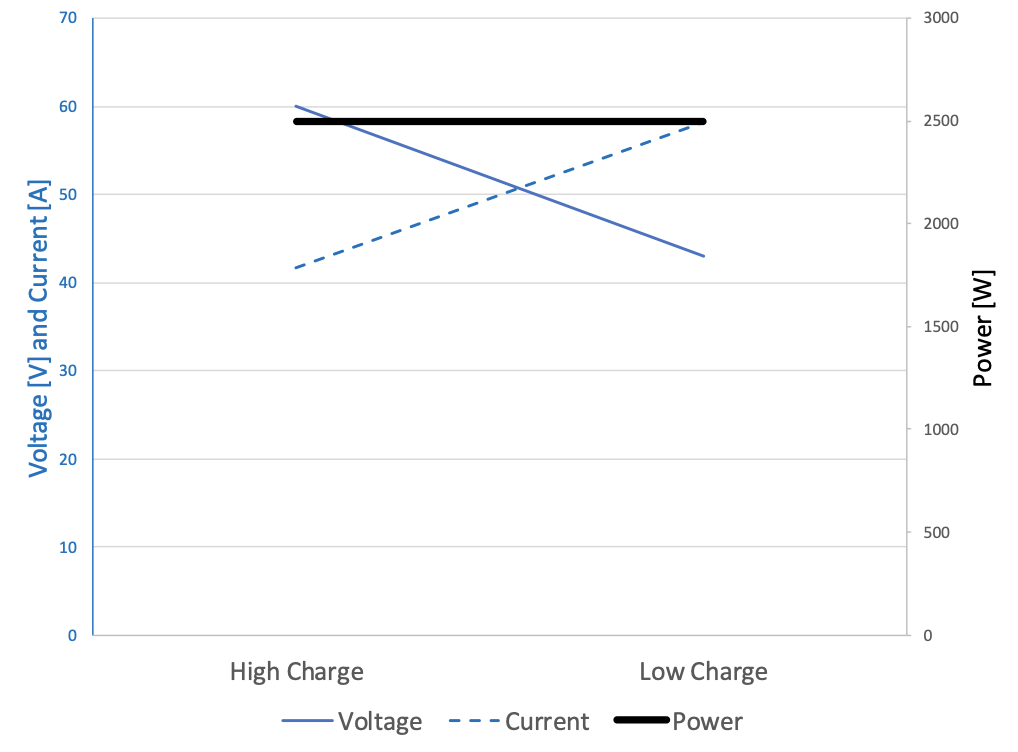

Using the collected data our engineers can look at the karts acceleration and torque values, electrical power and current to asses the batteries’ performance, throttle position and motor speed to asses the drivers behaviour and many more data and maths channels. Comparing and analysing this data will tell us if there is a drivetrain performance issue from the kart. If the analysis comes back all clear but the driver still feels it’s not right, when the kart returns to the factory it will be tested on the dyno.

What we do back at the factory

If the results from the dyno come back to say that there is a difference in the wheel power compared to what we would expect, we know one of two things is possible: either the motor is producing less power, or there is more friction in the chassis and drivetrain, giving the illusion of less power. Due to the motors having exceptional power tolerances compared to petrol, the motor producing less power rarely happens, instead it’s more likely to be friction in the drivetrain. If we find this happening in any of the karts, the kart is passed over to the mechanics who strip it down and investigate for causes of extra friction (such as axle bearings not performing like they should be).

The kart will also take a trip onto the chassis jig which will make sure the chassis is straight. Using the chassis jig, we can check a variety of measurements to find out if it’s twisted (looking from the front), bent (looking from the side), the position and angle of the yokes, the ride height and more. After this is done, the kart will be returned to the engineers and re-tested on the dyno.

In the unlikely event that there is still a difference in performance which can’t be found, we then arrange track testing where a datalogger is fitted on the kart and all its batteries, which is compared to a kart that is performing as expected. Through data analysis, lap timing and simulation, we will be able to see where on track and under what conditions there is a performance difference, providing us with more information to understand the basis of it being reported to be slow.

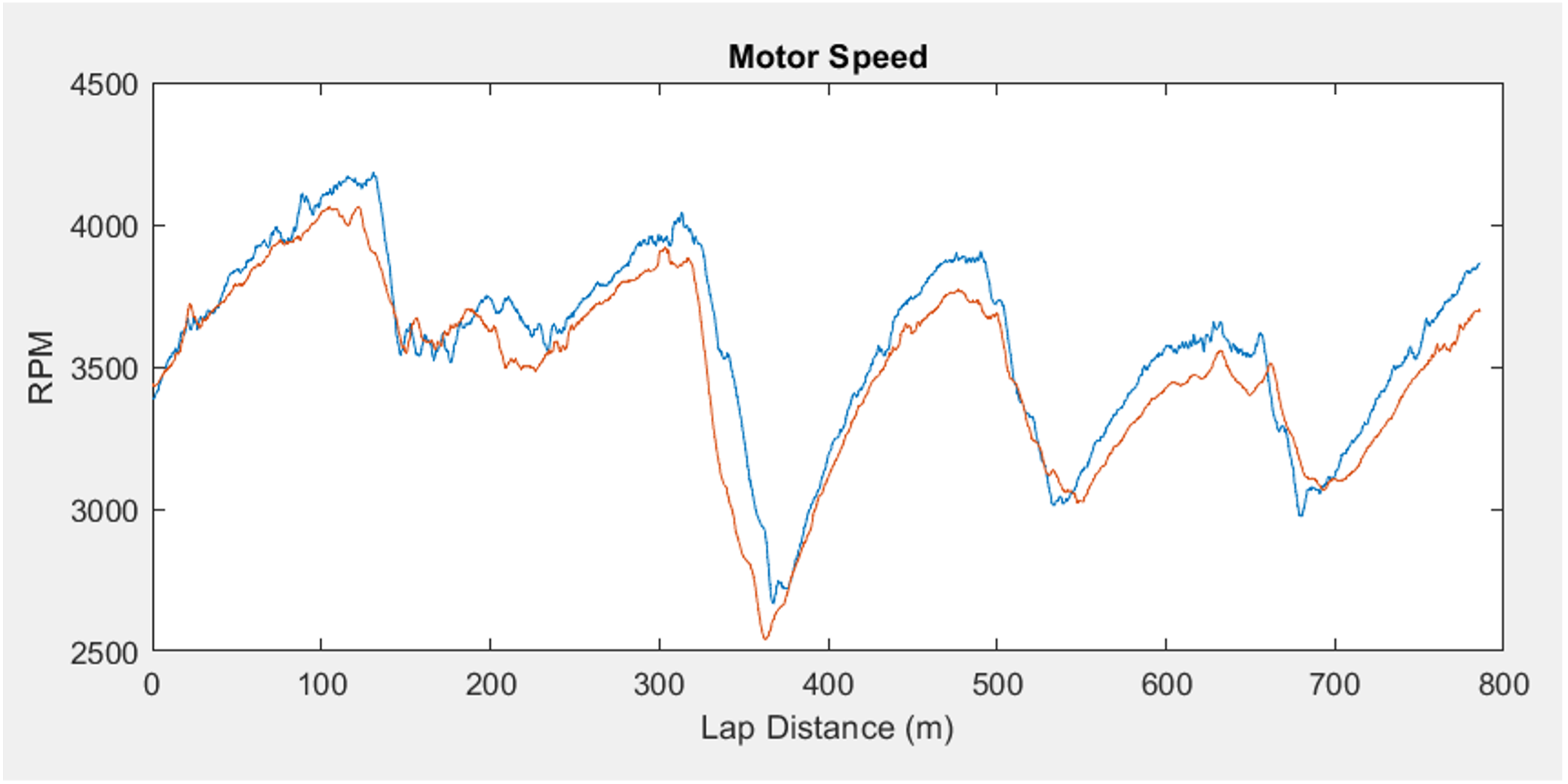

Here is an example of one data channel we would look into- comparing motor speed for two different karts.

In this instance there is no difference in power. The difference in motor speeds are a result of different driving styles and minimum apex speeds.

These are both bambino e-karts and the key to driving them quickly is maintaining momentum through the corners, therefore a small difference in minimum apex speed causes significant time differences down the next stright. This is why it can be difficult to judge by eye exactly what is going on- differences in speed on the straights are almost always causes by differences in cornering speed that are too small to be seen when taking into account different lines and driver behaviour.

As a summary- if a kart is reported to be under or over performing, the engineers analyse its performance at the track. Back at the factory, they are tested on the rolling road, mechanically stripped down and inspected, retested, and potentially track tested where necessary as well, allowing us to maintain parity and fairness in the TKZ championships.