THE TECH DIARY:

Bespoke Design

Will Sherwood | Technology Team

Total Karting Motorsport

In the last diary, you heard how we are striving to make motorsport fairer and faster, but how are we making it cheaper while maintaining the same quality? This starts with the designers at the drawing board. This diary will take you through that process. So, without further ado, lets start with some fundamental principles.

Principles of Design

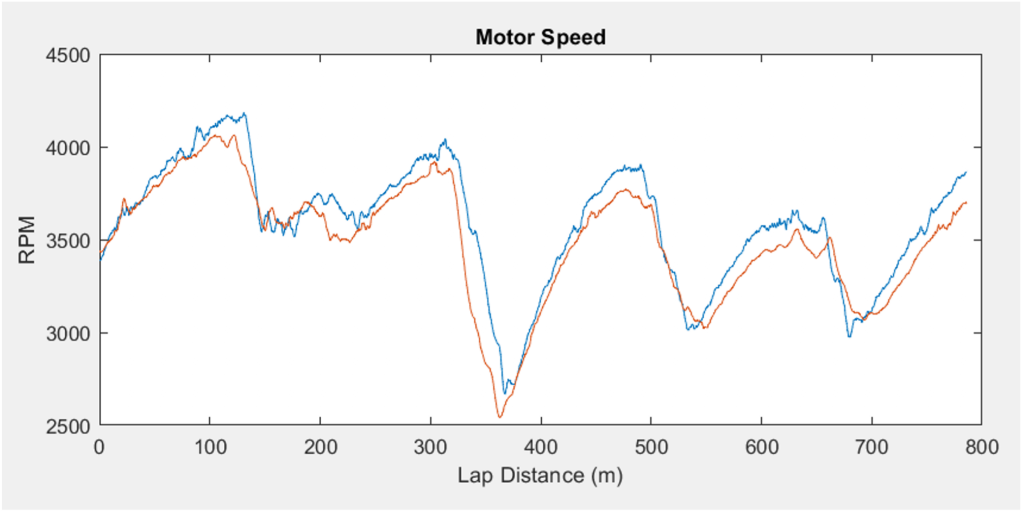

Design is all about process and planning. We take many different design styles and try and implement them to improve the final product. By improving the planning of our engineering projects we can pass on the saving to the customer by making key decision early on in the lifestyle of a kart.

Figure 1: Opportunity cost graph for Product life-cycle

There are many other design principles that we can utilise during the next steps in the design process which we will explore shortly. Looking back to the karts themselves its clear to see at a glance that there are not a lot of options for mounting exotic power-train components to the kart. It is not a surprise then that we have had to undertake a variety of bespoke engineering efforts to get our components to fit on the chassis that is designed for two stroke petrol engines. So, lets looks at some examples.

Design Work

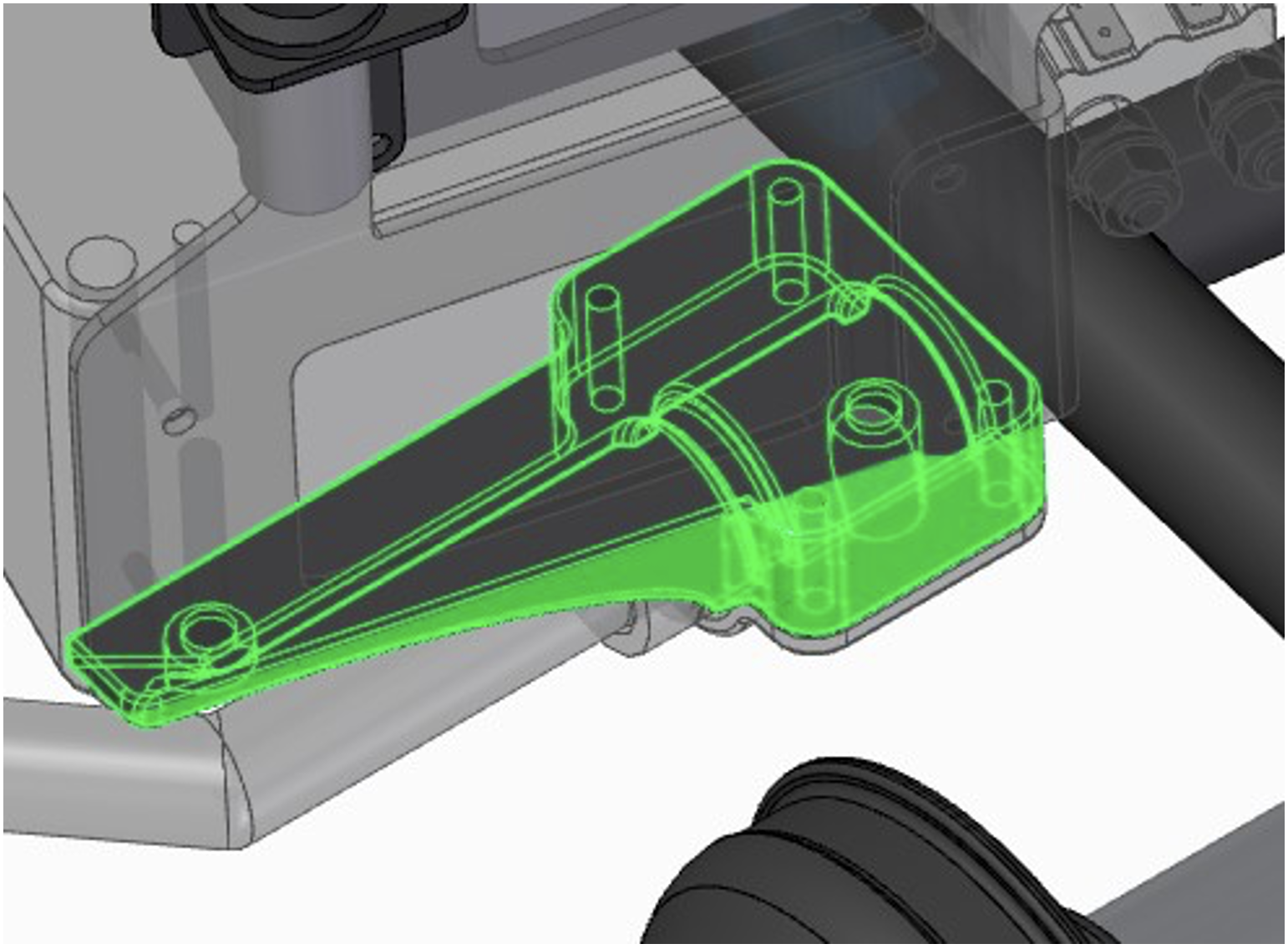

In order to fit the wide array of components to the karts we use the modular design concept; where elements of a design are compatible with other products. An example of this is the motor assembly on the Cadet and Bambino which are the same, and the battery assemblies on the Cadet and Junior karts are the same. We do this to exploit economies of scale when manufacturing the parts as higher quantities lead to a decrease in unit cost and therefore lowered price in the series.

We utilise Computer Aided Design (CAD) and simulation software to design and develop these components to ensure that they are both lightweight and strong.

We do this in order to make savings in the manufacturing process, which are:

- Time (because the component requires less material)

- Energy (because the machine producing the component is able to make it in less time)

- Money (because the component requires less time and material)

These not only help us reduce the end price but also reduce the environmental impact. We’ll discuss later how this process allows for the use of slightly less energy in the batteries when running, however first let’s look at an example of a design:

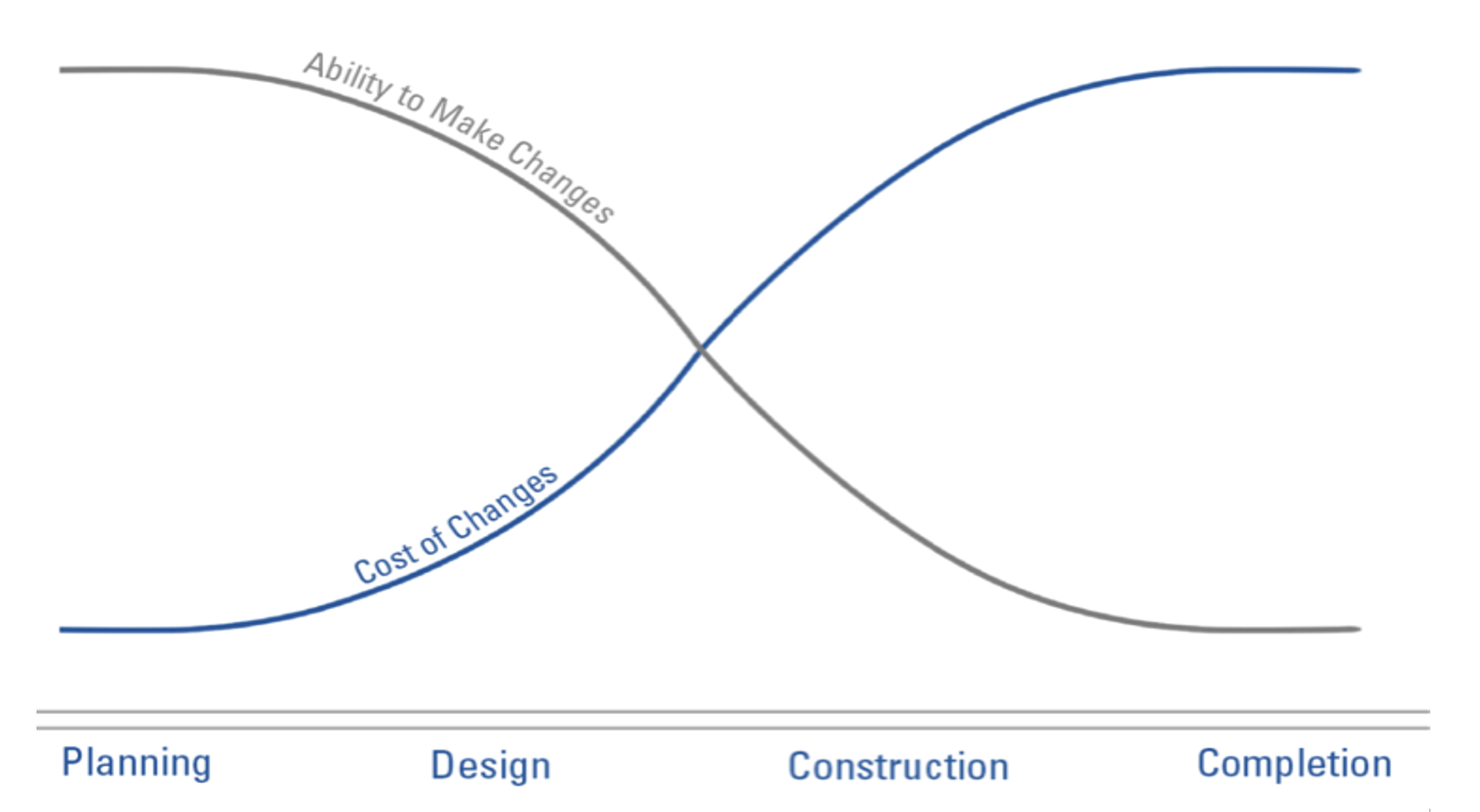

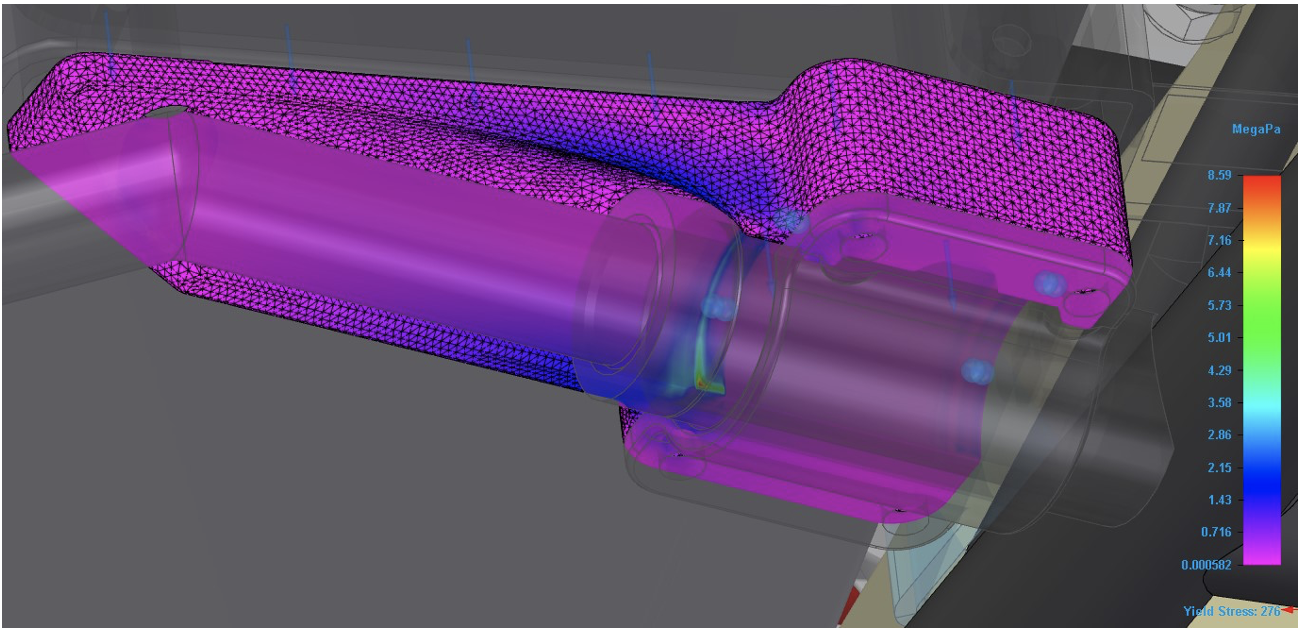

Figure 2: Finite Element results, colder colours indicate less stress.

Taking a rear battery mounting component for this example, we used Finite Element Modelling (FEM) (a part of the CAD process) to show how well the proposed lightweight design of this particular component would hold up to the load of the battery. The below visual shows that the stresses in this component are very low, which indicates that the component will perform its required job, without having to produce costly prototypes that may not work initially and therefore require re-design. Using similar methods to Formula One, this process is a way of validifying our designs by analysing FEM results.

Figure 3: Shown is the Junior rear left battery frame mount.

Manufacturing Processes

Once we are happy that the component will perform it’s function, whilst being more lightweight, we have to think about how we are going to produce it. For this, we have two options:

- For complex shapes, we can utilise machines that use Computer Numerical Control (CNC) to cut metal in certain ways. This is often expensive, but can be more effective for this level of complexity

- For simpler parts, we can bend flat sheet metal into the shape we need. An example of this on our karts are the brackets used for mounting the electric motors.

Effect on performance

Through the design and manufacturing process we have now made a component that is light weight, but let’s now look at why weight is an important consideration in the first place. We will do this using Newton’s second law equation:

Force = Mass x Acceleration (F=ma)

When F (thought of as the forward force produced by the motor) is held constant and the mass (m) reduced, acceleration (a) will increase which means better performance.

Additionally, this also works in reverse.

With the assumption that the force is roughly constant then again we will have higher decelerations that means shorter stopping distance.

This will also mean that the energy dissipated by brakes is lower and therefore brake temperature is reduced stressing less the braking system.

Up to this point, everything we have talked about affects acceleration and braking, but how does this affect performance when cornering and why is it important to consider in the design process? To answer those questions, we’ll need a whole new tech diary to explain those details!

More from the Tech Diary

Blog | October 2022

Author: Sammy Bryan | Technology Team

The efficiency of any mechanical system is never going to be identical however, the power output of electric motors is a lot more controllable than petrol engines: petrol engines have…

Stay in the loop

Want to be informed when the next Tech Diary post is out? Subscribe below: