THE TECH DIARY: Reliability, an update

Sammy Bryan | Technology Team

Total Karting Motorsport

Anyone who races will eventually experience something similar, whether in your own kart or a hire kart. It’s just as painful for the team and the TKZ family as it is for the driver when a kart doesn’t finish a race- we take it personally because our hard work and dedication on that occasion didn’t pay off. That’s why we take reliability very seriously and dedicate so much time, effort and money to improving it. Let’s take a dive into exploring how we have improved and continue to improve the reliability of the TKZ E-Karts.

RECORDING

Every reliability issue that occurs during championship weekends, testing and SPARKS events is recorded by one of our engineers. It’s then discussed by the whole technical team, mechanics, customer liaison and anyone who wants to join, keeping everyone both well informed and allowing their contribution to solving the problems faced. This (often quite lengthy!) meeting gives us the chance to fully understand what went wrong, why it happened and most importantly, how we can prevent it from happening in the future. It’s only with diligent information gathering, detailed assessment and high-quality work that reliability will improve long term.

Changes we have made already are clearly working- comparing the end of the 2021 summer season to the start of the 2022 summer season we saw roughly half the number of reliability issues per kart at each event (46% reduction in bambino and 52% in cadets). This has improved further since then- the graph below compares the last 3 events in 2021 to the most recent 3 events. It shows a 71% reduction in bambino issues and 58% reduction in cadet issues.

The graph below shows the improving trend in reliability in more detail by splitting it into events during the first part of the 2022 season. We can see the downward trend which continued into the second part of 2022 and the current winter championship too-

at winter round 2, Rye House, we experienced for the first time no cut-outs or on-track stoppages of any Junior kart, despite having the full fleet racing. At the same race event, there was only one Bambino and one Cadet stop on track, neither of which were drivetrain issues. When we compare this to a typical event from 2021, there’s a world of difference; 18 months ago if we had ten bambinos racing, we would have prepared to experience and fix as many issues, whereas today we would expect less than one.

ANALYSING

How have we made these reliability improvements? This is done not just through changing parts to upgraded versions, in fact very little has changed on this Gen1.6 E-Kart since its introduction a year ago- we’ve only tweaked the design of some pedals, everything else is the same as at time of launch in Spring of 2022. The majority of reliability improvements have come from how we understand the karts and therefore how we operate. We have implemented a much more stringent method of recording reliability issues in as much detail as possible and this allows us to go into a lot of detail when analysing trends, causes and effects. From this detailed database we have created a more thorough 41-point checklist that every kart must pass before being loaded into the lorry prior to the race weekend.

In addition to this, the level of checks on the powertrain during the event between sessions has improved in both detail and frequency. We can now see the health of the batteries and individual strings of cells before each session. This allows us to spot small issues with the batteries before they develop into bigger issues that would end a race. An example is shown on the left. This has helped us notice several issues with batteries before the session starts, so these can be resolved or the kart swapped.

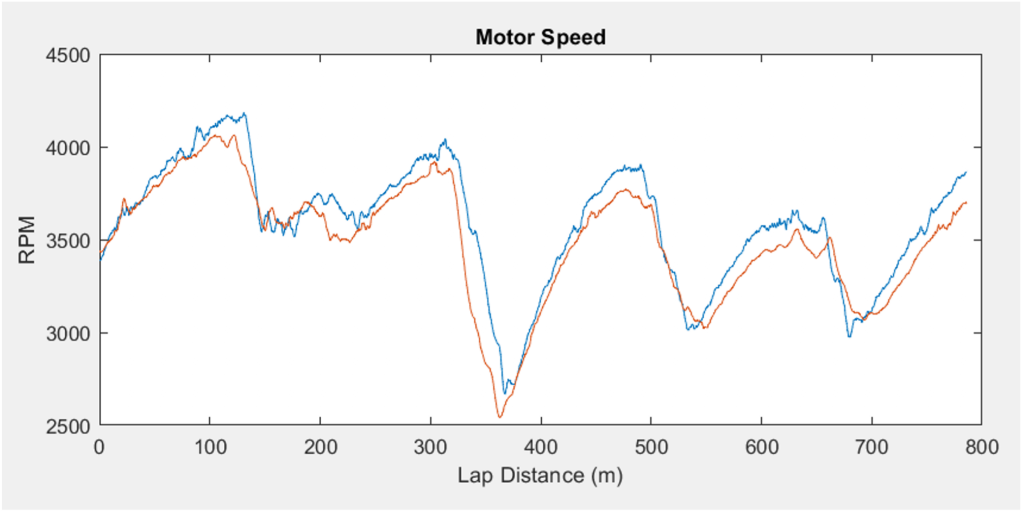

It’s not only the batteries that we know more details about and better understand how they work, but also the motor and control unit. Just like the engine map in a petrol car, the E-Karts have a map for the electric motor. This map controls how much current is drawn from the batteries based on throttle position, and therefore how much power is given to the motor. The map has been tweaked, fine-tuned and made more efficient over the course of the year which has made the karts more powerful as well as lasting longer on track and being more reliable.

TKZ’s 1.6 E-Kart was a development of the original 1.0 E-Karts and it was always intended to use 2022 to significantly develop the platform. Now however, the rate of development has

slowed down because the reliability is reaching its target. That’s not to say it’s 100%- there will always be issues, but every failure will contribute to preventing the same issue re-occurring.

The next generation of TKZ E-Karts is currently set to be a totally new design that is built upon the wealth of knowledge and understanding we have accumulated during 2022 and preceding years. These karts, which are in the advanced stages of development, will be more powerful, faster and will undoubtedly continue to improve the reliability so that the drivers can push hard knowing they’re going to make it to the finish every time they step into a TKZ E-Kart.

More from the Tech Diary

Blog | October 2022

Author: Sammy Bryan | Technology Team

The efficiency of any mechanical system is never going to be identical however, the power output of electric motors is a lot more controllable than petrol engines: petrol engines have…

Stay in the loop

Want to be informed when the next Tech Diary post is out? Subscribe below: